Symoil Engineering

Step 1

Design Process

Latest versions of engineering software in our head office.

Three 3D printers are used for better visualizing capabilities during idea generation.

Step 2

Manufacturing

Manufacturing takes place in our partner manufacturing facility.

Here we are able to quickly manufacture any equipment required for our projects.

Step 3

Certification and Validation

Our multiple in-house testing capabilities are designed to test tools to their limits. Certification to GOST/ISO & API requirements is done at Symoil’s testing facility.

Step 4

Commercialization

By having comprehensive operational and service facilities, tools can be quickly developed and manufactured ready for commercialization in most places in the world where services can be provided.

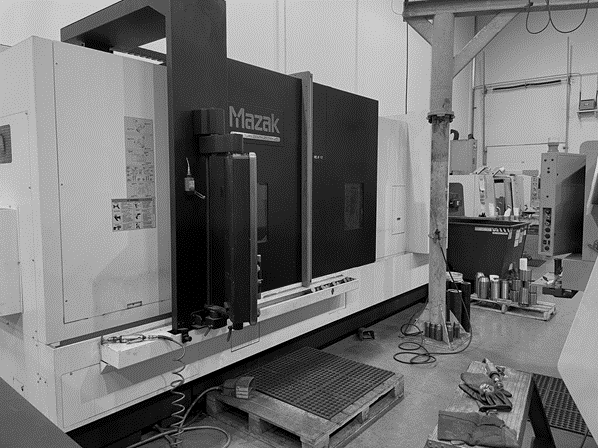

Partnering Manufacturing Site

Machining Facility

Situated in Calgary, Canada, it is ideally located within the oil and gas hub. The facility has the necessary skills and expertise to rapidly provide machined parts using CNC Lathes and Milling Machines in a modern facility. With an ever changing and challaging schedule the machine shop is able to combine this with an in-house Surface Treatment capability.

"Symoil has implemented an effective QA/QC documented inspection process to ensure that critical component checks is completed to ensure all machined and manufactured product meets the desired design specifications. Starting from the design manufacturing stages throuh to the eventual use of the tool in the Customer’s well the company’s aim is for zero defects and product quality assurance”

Symoil Research & Development

R&D Testing and Assembly facility

Situated within our largest services facility, this area is mainly used for

testing and validating the Multi-Stage Stimulation equipment with High

Pressure, High Temperature and High-Flowrate.

All testing is recorded and can be witnessed online through our inhouse cloudbased system.

High pressure testing area

Full spec out to perform ISO14310 / API 11D1 V3 Packers and Liner hanger liquid validation testing up pressure to 1000 Bar /15.000 Psi and 200C / 400F

Openhole Packer testing according API 19OH

Long travel rams for controlled shifting and manipulation of sleeves

Pressure testing and functionality testing for Downhole tools

Cloud-based High Resolution DAQ system

Laboratory facilities

250degC Oven (for Magnesium Alloy dissolving testing)

Mixing and weighing equipment

High-Flow-rate Area

20 meter long indoor Liner-Simulation-flow-loop-system with build-in

flud reservoir

Capable of pumping 1000 liter/min for simuating darts landing, and

our other proprietary multi-stage stimulation technologies.

All testing is recorded and can be witnessed online through our inhouse cloudbased system.

High pressure testing area

Laboratory facilities

High-Flow-rate Area

R&D Testing and Assembly facility

Situated within our main manufacturing facility, this area is used for the majority of testing and R&D for Symoil’s Packer Technologies

With 200m2 available space for assembly and high pressure testing, the area is ideal for validation testing for Packers, Sleeves and Liner Hangers.

200 m2 of assembly and high pressure testing area, ideal for validation testing of Packers, Sleeves and Liner Hangers.

Controlled Sleeve Shifting and pressure testing

API 11D1 – V3 Validation testing equipment up to 15K and 400F