About

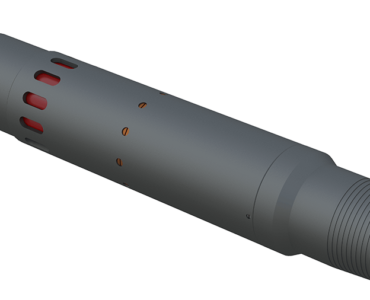

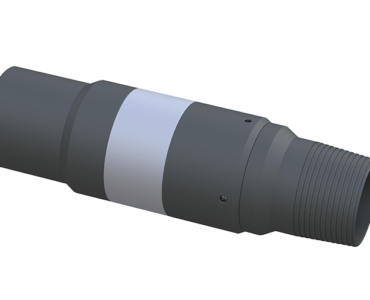

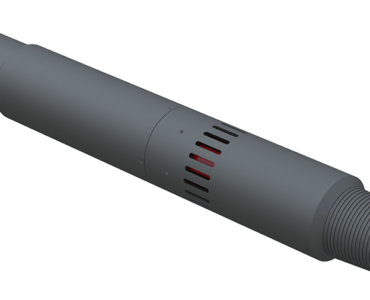

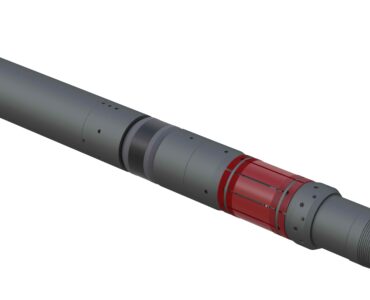

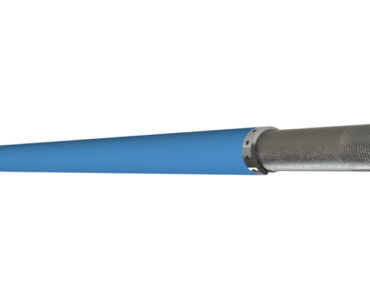

Symoil floating equipment is used to guide the casing to set in the hole and ensure the quality of cementing. It is widely used in the lower section of the well to help decrease strain on the derrick while directing packaging past edges and bog zones in the opening.

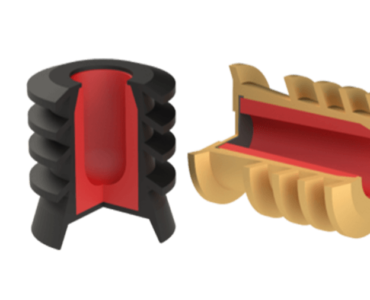

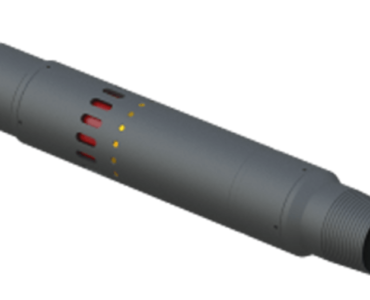

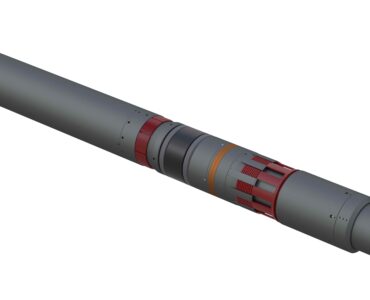

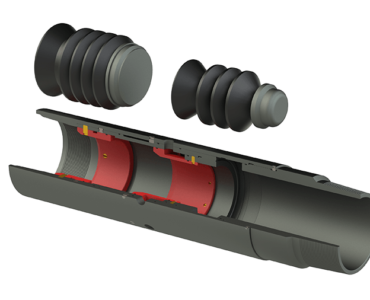

The floating equipment contains a backpressure valve that prevent fluids from entering the casing while the pipe is lowered into the hole and prevents cement from flowing back into the casing after placement, while enabling circulation down through the casing.

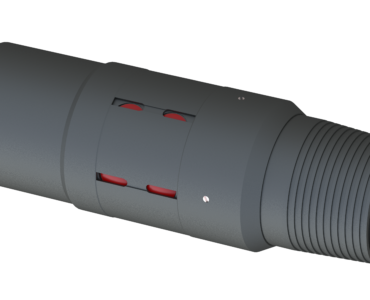

The float collar is run in a casing assembly, usually several joints above the float shoe. It provide a seat for the cement plugs, to help top plugs shuts off fluid flow and prevents over-displacement of the cement. The space between the float shoe and float collar provides a containment area to entrap the likely-contaminated fluids from the wiping action of the cementing plug, securing the contaminated fluid away from the shoe where a strong cement bond is of primary importance.