About

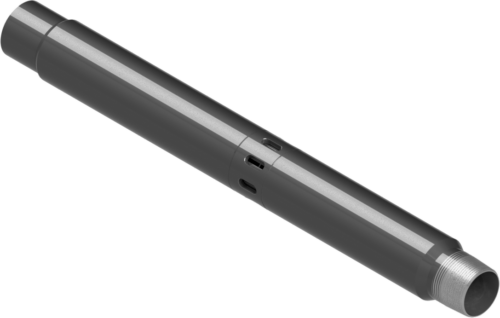

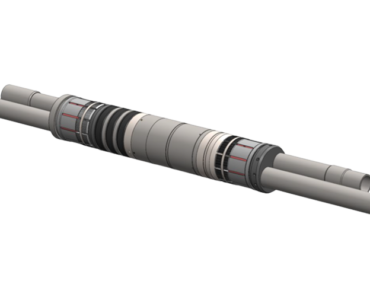

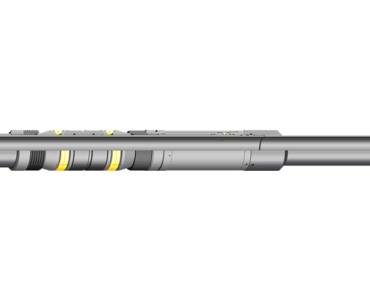

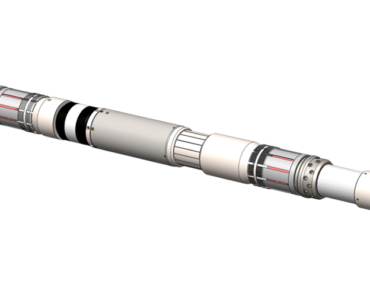

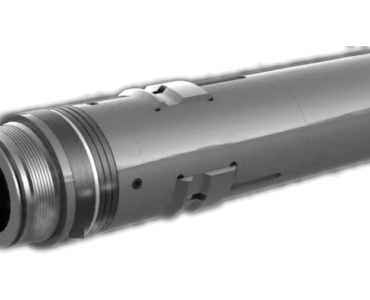

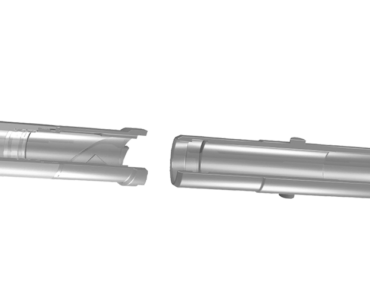

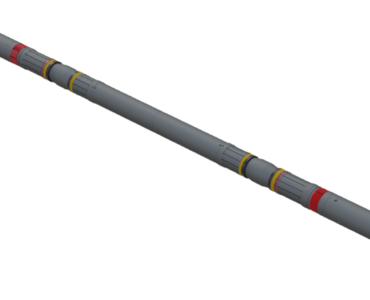

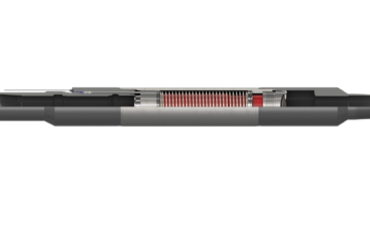

Sliding Sleeve Door for shifting tools can be selectively shifted open or closed to open communication for tubing to wellbore.

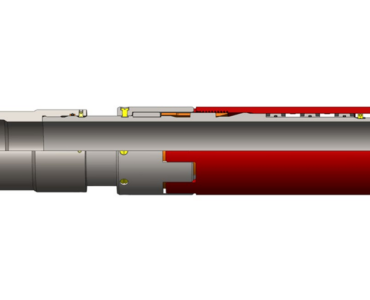

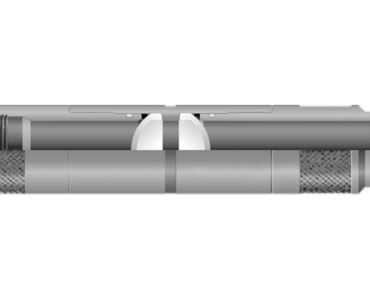

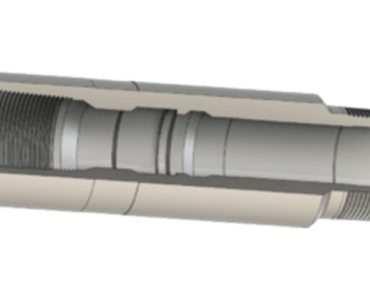

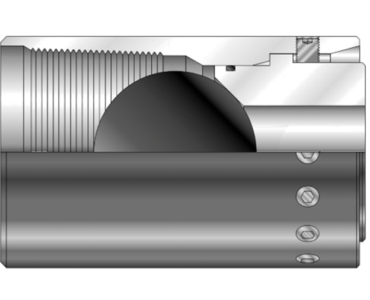

The Sliding Side-Door circulation and production sleeve is a full opening device with an inner sleeve that can be repeatedly opened and closed to gain communication between the tubing/casing annulus. A nipple profile in the top sub and a polished bore in the bottom sub are standard features, which allow accessory tools such as a Side-Door choke or separation tool to be set across the Sliding Side-Door.

The Sliding Side-Door utilizes Non-Elastomeric seals eliminating any elastomers from the tool. These seals provide a more easily shifted sleeve while providing reliable service for the life of the well.

Features

| Tubing | Tubing ID – in – [mm] | Seal Bore – in – [mm] | ||

|---|---|---|---|---|

| Tubing Size – in – [mm] | Tubing Weight [lb/ft] | Wall Thickness [mm] | ||

| 2,375 – [60,3] | 4,6 – 4,7 | 4,8 | 1,995 – [50,7] | 1,875 – [47,6] |

| 2,875 – [73] | 6,4 – 6,6 | 5,5 | 2,441 – [62] | 2,312 – [58,7] |

| 3,5 – [88,9] | 9,2 | 6,5 | 2,992 – [76] | 2,812 – [71,4] |

| 10,3 | 7,3 | 2,922 – [74,2] | 2,75 – [69,9] | |

| 4 – [101,6] | 10,9 – 11 | 6,7 | 3,476 – [88,3] | 3,312 – [84,1] |

| 4,5 – [114,3] | 12,6 – 12,75 | 6,9 | 3,958 – [100,5] | 3,812 – [96,8] |

| 4,5 – [114,3] | 15,2 | 8,6 | 3,826 – [97,2] | 3,688 – [93,7] |